AggreDust

AggreDust: the go-to solution for overcoming the harmful side-effects of dust on people and the environment

Overview and Introduction to AggreDust

Dust plagues construction sites, agricultural fields, and even urban areas, creating a multitude of problems for health, safety, and the environment.

AggreDust is a copolymer designed for dust suppression, sand control, slope stability, and environmental applications. It provides a flexible, yet strong, cohesive bond for a wide range of materials and forms a durable surface coating with good wind resistance and water-resistant properties, that effectively binds soil particles together, reducing dust emissions by up to 95%. It is environmentally friendly, cost-effective, versatile and easy to use requiring minimal equipment and manpower.

The Root Causes of Dust

Construction Activities

Earthmoving, excavation, demolition, and vehicle movement on unpaved surfaces and dirt roads that stir up dust particles.

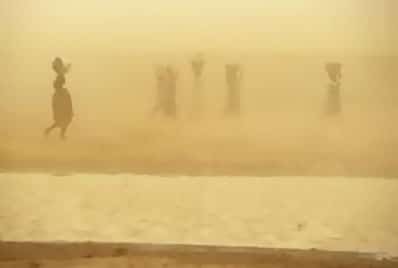

Wind Erosion

Exposed soil and stockpiles become vulnerable to windblown dust (fugitive dust), especially during dry and windy conditions.

Material Handling

Loading, unloading, and stockpiling of dry materials like sand, gravel, and soil generate dust clouds.

Land Clearing and Deforestation

Removing vegetation exposes bare soil, making it susceptible to wind and water erosion, leading to dust generation and sediment increase in water runoff (NTU).

Mining

Excavating, tunnelling, grinding, hauling, stockpiling tailings, etc, are all causes of fugitive dust, with a percentage of the dust being toxic.

Agricultural Practices

Tilling, harvesting, and other agricultural activities can disturb soil particles, contributing to dust emissions.

The Far-Reaching Impact of Dust

Dust isn’t just an eyesore; it poses significant problems for our environment and well-being:

Health Hazards

Dust inhalation can cause respiratory problems like asthma, allergies, and even lung diseases like silicosis. This is especially harmful for construction workers, farmers, and residents living near dusty areas.

Reduced Crop Yields

Dust can settle on crops, hindering their growth and reducing yields. Additionally, windblown dust can carry harmful pathogens, impacting agricultural productivity and food safety. And the settlement of dust on crops creates the ideal environment for insect infestation.

Environmental Degradation

Dust storms can erode topsoil, leading to reduced soil fertility and impacting ecosystems and biodiversity. It can also pollute waterways (increased NTUs) and disrupt natural habitats.

Infrastructure Damage

Dust can accumulate on roads, bridges, and other infrastructure, causing wear and tear and requiring increased maintenance costs.

Pests and Disease

Dust can create favorable conditions for pests like rodents and insects, potentially transmitting diseases to humans and animals, and creating an increased use of crop chemicals.

Reduced Visibility

Dust clouds can impair visibility, leading to safety hazards on roads and construction sites.

AggreDust: The Solution to Conquering Dust

AggreDust emerges as a powerful solution to combat these dust-related challenges. By effectively binding soil particles together at the surface, it creates a stable, dust-free surface layer, improving air quality, preserving soil health, creating safer working conditions, controlling pest populations and promoting work, health and safety in the workplace.

By choosing AggreDust, you’re not just controlling dust; you’re investing in a healthier environment, sustainable practices, and the well-being of your workers & community.

Advantages:

Solvent-free system

Easy-safe handling

No leaching or dissipating into soil

Forms clear film after curing

Can be easily diluted to suit different applications

No change in appearance of the treated surface

Rapid deployment (4-5 acres can be done in 2 days)

Understanding the AggreDust Process and Method Statement

AggreDust’s application process is straightforward and efficient, designed to minimize disruption to works and ongoing operations.

Site Investigation

A site investigation is a vital part of the process to understand the type of soil we are working with, what areas will require the dust control, site accessibility and usage of the site to consider our application.

Area Preparation

Preparation is key to a great result and the area should be prepared prior to application. For temporary roads, the area should be compacted, pipes protected, and pipe berm readied, and areas for dust control identified.

Solution Mixing

The AggreDust solution is prepared inside the water truck following the Method Statement instructions. All accessories including hose and nozzle should be assembled correctly.

Solution Application

The AggreDust solution is applied with a low base, soft spray to ensure uniform distribution and penetration to avoid surface erosion.

Crust Inspection

For areas where AggreDust has been applied, an inspection of the 24-hour crust should be completed to confirm hardness, penetration and water absorption.

Contact one of our globally based Dealers or Registered Suppliers for an AggreBind Solution for your project.

From Vision to Reality: Real-World Examples of AggreDust in Action

AggreDust isn’t just a product; it’s a powerful tool that introduces innovative dust control solutions to projects across

renewables, construction, transport, agriculture, mining and the hard to abate sector.

Dust Control on Unstable base

Slope control on unstable base

BIAL Kempegowda Intl Airport

AggreDust in livestock and farming

Dust Control for Agriculture

Common questions (FAQs) about Dust Control and AggreDust

What is the difference between an AggreDust and a RoadMaster implementation?

AggreDust is a topical treatment that stabilises the surface soils, where a RoadMaster project will create a rock solid road base to a depth appropriate to the tonnage of the vehicles and traffic it carries. Where longevity and low ongoing maintenance is preferred, our team will recommend RoadMaster.

Can you use AggreDust for a road?

Yes. AggreDust has been successfully used for low volume roads where a stable base of compressed dirt already exists. An AggreDust implementation should be used on roads where traffic does not stop or turn but rather maintains a consistent momentum.

Can you walk on AggreDust once it has dried?

There are many factors that will determine this. Where AggreDust has been used on a solid and compressed base, then yes, it will be like walking on any road. Where AggreDust has been used on a non-stabilised base it will depend on the soil characteristics it covers, as well as the dilution ratio used.

What dilution rate to water, do you use for AggreDust?

The dilution rate to water will depend upon the desired project outcome. Where AggreDust is used for moisture retention for seedling regeneration on solar farms, a high dilution is recommended to ensure the seedlings are able to growth through the layer. Where a solid cap is required, for example over a tailing pile or coal pile, a lower dilution rate will be recommended. Our method statement, installation protocol and supplier will discuss your project with you, for your outcomes.

How does AggreDust compare to traditional dust suppression methods?

The traditional method of dust suppression in construction is through the use of water trucks which pass several times a day and have limits relating to water availability and water costs, as well as the ongoing costs of labor, gas and environmental issues of running the water trucks consistently over the period of construction. AggreDust has been used successfully both as a one off dust suppression solution on construction sites, and also as a water retention layer to encourage vegetation growth and tree barriers. AggreDust is a single, long-lasting solution for dust control.

How long does AggreDust last and how often does it need to be reapplied?

AggreDust is a long-lasting dust control solution. Maintenance needed will depend upon the project, the dilution rate needed and your outcomes.

Can AggreDust be used in environmentally sensitive areas?

Yes. AggreDust is non toxic, non hazardous and environmentally friendly. It has been independently tested and approved for use in many sensitive areas including National Forests, Antarctica and Native Lands. We are always delighted to share these independent test reports with our clients if you would like to contact us to discuss your project and outcomes.

Is there any impact on worker health and safety?

AggreDust supports worker health and safety by removing up to 95% of dust pollution. It enables a good neighbor policy for industry by ensuring that airborne dust particles are reduced and not carried to nearby agricultural lands, residential areas and cities.

Are there any case studies or testimonials on the effectiveness of AggreDust in reducing dust?

Where we are able, we share the trial videos for our project and these can be viewed below. We have many testimonials and attestations by clients and are delighted to share these with our clients, as they are relevant to your project and outcome. Contact us here to start the conversation with an AggreBind Registered Supplier.

What kind of equipment is required to apply AggreBind?

Once mixed to the correct dilution, AggreDust is applied via spray. Depending on the project size, it can be sprayed from a water-truck, a trolley or a back pack.

Unmasking the Hidden Costs of Dust: A Deeper Look at Problems and Solutions

Dust poses a multitude of problems that affect our health, the environment, and various economic sectors. For each of these dust-related issues, there’s a corresponding AggreDust solution waiting to be implemented.

Dust Control Of Gravel Roads

Issue

Solution

Dusty gravel roads generate dust when vehicles drive through, obscuring vision and possibly causing accidents..

Binds surface particles together thereby reducing dust generation.

Issue

Dusty gravel roads generate dust when vehicles drive through, obscuring vision and possibly causing accidents..

Solution

Binds surface particles together thereby reducing dust generation.

Dust Control Of Sand Dunes

Issue

Solution

Sand dunes migrate onto roads causing accidents and hazards.

Forms a crust that prevents the migration of sand onto the road.

Issue

Sand dunes migrate onto roads causing accidents and hazards.

Solution

Forms a crust that prevents the migration of sand onto the road.

Pipe Berm Protection

Issue

Solution

Pipe berms become exposed due to strong winds and heavy rains. Bitumen emulsion topping is not an environmentally friendly covering.

Applied over the berm’s soil surface is an environmentally friendly solution to protecting the pipes from becoming exposed.

Issue

Pipe berms become exposed due to strong winds and heavy rains. Bitumen emulsion topping is not an environmentally friendly covering.

Solution

Applied over the berm’s soil surface is an environmentally friendly solution to protecting the pipes from becoming exposed.

Dust Control Of Solar Farm

Issue

Solution

Build-up of dust on the solar panels decreases solar power generation. Dust from cleared solar farms creates environmental issues through silt runoff into waterways.

Applied in the area and on the roads of solar farms will reduce dust generation and mitigate the accumulation of dust on the panels.

Issue

Build-up of dust on the solar panels decreases solar power generation. Dust from cleared solar farms creates environmental issues through silt runoff into waterways.

Solution

Applied in the area and on the roads of solar farms will reduce dust generation and mitigate the accumulation of dust on the panels.

Dust Control Of Helipad

Issue

Solution

Helicopters generate significant downforce during, which churns up dust and debris, obscuring visibility and damaging sensitive equipment.

Suppresses dust on the landing area, locking it down to the surface. Regular monitoring of conditions for safety and operations is crucial.

Issue

Helicopters generate significant downforce during, which churns up dust and debris, obscuring visibility and damaging sensitive equipment.

Solution

Suppresses dust on the landing area, locking it down to the surface. Regular monitoring of conditions for safety and operations is crucial.

Slope Control

Issue

Solution

Sloped soil surfaces are vulnerable to soil erosion due to run off from rain and from wind.

Creates a protective layer to slopes. Enhances soil’s cohesive properties and improving stabilization. Mitigates water infiltration to slope.

Issue

Sloped soil surfaces are vulnerable to soil erosion due to run off from rain and from wind.

Solution

Creates a protective layer to slopes. Enhances soil’s cohesive properties and improving stabilization. Mitigates water infiltration to slope.

Dust Control For Mines & Quarries

Issue

Solution

Degradation and erosion of quarry surfaces from extreme temperatures, moisture, and chemicals jeopardizing the stability of excavation activities.

Reinforces the quarry’s structural integrity and prevents soil erosion. Secures the tailings without daily watering. Reduces dust inside tunnels.

Issue

Degradation and erosion of quarry surfaces from extreme temperatures, moisture, and chemicals jeopardizing the stability of excavation activities.

Solution

Reinforces the quarry’s structural integrity and prevents soil erosion. Secures the tailings without daily watering. Reduces dust inside tunnels.

Join Us In Shaping The Future

With AggreBind Solutions

Subscribe To Receive Our Project News