RoadMaster: Redefining

Road & Road Base Construction

Setting the benchmark for environmentally friendly,

rapid deployment, resilient road and airstrip solutions

Setting the benchmark for environmentally friendly, rapid deployment, resilient road and airstrip solutions

Stronger Roads for a Sustainable Future: Introducing AggreBind RoadMaster

Our planet faces immense challenges, from climate change and resource scarcity to growing infrastructure needs. In the face of these pressures, the roads we build must be more than just arteries of transportation; they must be resilient and sustainable. AggreBind RoadMaster offers a revolutionary way to build roads that are strong, durable and kind to the environment, lowering the carbon footprint of construction.

RoadMaster is more than just a soil stabilizer; it’s a commitment to a brighter future. By harnessing the power of AggreBind’s patented technology, we transform weak, unstable soils into durable foundations for roads, airstrips, and any ground surface demanding exceptional strength. Whether facing light car traffic or the heavyweights of mining operations, RoadMaster adapts its depth to create a surface that endures. It’s time to build stronger, more sustainable roads that pave the way to a future where infrastructure and environment can thrive together.

Conquer Roadbuilding Challenges with AggreBind RoadMaster

Here are the biggest challenges RoadMaster tackles head-on.

Taming Untameable Soils

Conventional methods of road construction often struggle with weak, or unstable soils, especially in remote locations where aggregates are not readily available, leading to costly failures and increased maintenance. RoadMaster’s long-string cross-linking formula strengthens even the most challenging soils, creating a rock-solid foundation for any road.

Potholes and Maintenance

Potholes are an eyesore, and safety hazards. Conventional repairs are temporary, ignoring the underlying problem of heating, cooling and moisture within the sub-base, leading to a cycle of re-fixes. RoadMaster is long-lasting, durable with hydrophobic properties and impedes water ingress to resist damage caused by extreme climates and high-water tables, eliminating pothole formation and saving time and resources.

Dust Devils and Plumes

Unsealed and dirt roads contribute significantly to dust pollution, harming health and the environment. RoadMaster binds together the loose soil particles, effectively stabilizing the soil, controlling dust and creating a safer, cleaner environment for communities.

Quarrying and Aggregates

Quarrying and transporting materials are resource-intensive and environmentally impactful. RoadMaster utilizes on-site materials: reducing reliance on quarries, transport and introduction of foreign aggregates which lowers project costs, reduces carbon emissions and minimizes the project’s environmental footprint.

High Water Tables and Sub Surface Saturation

Ground water and rising water can wreak havoc on roads, causing erosion and weakening foundations. RoadMaster’s long-string cross-linking technology forms a water-resistant barrier, shielding the road base from moisture that can infiltrate and weaken conventional materials, ultimately preventing erosion from the bottom up.

Slashed Project

Timelines

Traditional construction methods can be lengthy, causing inconvenience, steep costs, and environmental disruption. RoadMaster’s swift implementation minimizes project downtime, reducing noise, dust, and environmental impact. An experienced crew can implement up to 2 kms of AggreBind road in less than a week.

Cut Project

Costs

Building roads often comes with a hefty price tag, limiting accessibility to infrastructure in rural areas and developing regions. RoadMaster’s time-to-implement, cost-effectiveness and reduced reliance on imported materials make it an affordable solution, enabling road development and vital infrastructure even in budget-conscious communities.

Equipment & Barriers to Implementation

Conventional road building equipment is expensive, and the scale of operations, limits the ability for construction for regional highways and sprawling road networks. RoadMaster requires minimal specialized equipment to implement making it a viable and sustainable solution for long and short haul road developments, even with limited infrastructure and budgets.

Beyond Roads: Where RoadMaster Shines

While RoadMaster excels in building strong, durable roads and infrastructure networks, its applications extend far beyond. Here are just a few examples of how RoadMaster’s versatility empowers the construction, aviation, and mining industries.

Low-Volume Roads and Driveways

Often plagued by dust and potholes, low-volume roads and driveways find new life with RoadMaster. Its ability to stabilize weak soils and create a durable, dust-free surface without the need to import aggregates, makes it ideal for rural roads, access roads, and driveways, reducing maintenance costs and environmental impact.

Road Bases

For residential and high traffic areas where an asphalt or bitumen seal layer is needed, RoadMaster can provide a cost-effective, durable, and sustainable base layer. By stabilizing the subgrade reducing asphalt thickness, and removing need to import aggregate, it minimizes material use, carbon footprint, construction time, and reduces project cost, all while offering a rock-solid base for the final asphalt layer.

Private and Commercial Airstrips

From remote locations, agriculture and private airstrips, rapid deployment operations and humanitarian interventions, RoadMaster has been the go-to product for safe and reliable airstrips for more than a decade. Its resistance to wear and tear, even under heavy aircraft traffic and frequent landings, minimizes maintenance needs and ensures a stable landing surface, even in harsh weather conditions.

Access and Haulage Roads

Dust, potholes, and erosion wreak havoc on roads within mining operations, renewables projects, agriculture access and new developments. RoadMaster tackles these challenges head-on, creating durable, dust-controlled haulage and access roads that withstand the weight of heavy trucks and mining vehicles, and protects the surrounding infrastructure and environment, reducing downtime and maintenance costs while promoting a safer working environment.

Parking Lots

Gone are the days of cracked asphalt and dust clouds in parking lots. RoadMaster provides a low-cost alternative that stabilizes soils, preventing potholes, rutting and damage to vehicles and property. Rapid implementation further cuts costs and environmental impact, while its dust-suppressing properties and durability further reduce long-term maintenance.

Bike & Mobility Paths

Forget bumpy rides and spacer maintenance! RoadMaster’s unique hydrophobic properties and temperature stability eliminates the need for spacers, creating a consistently smooth, crack-free surface for cyclists, pedestrians, personal mobility aids and families. Enjoy comfortable rides and reduced maintenance with an environmentally friendly and sustainable transportation network.

RoadMaster in Action: Project Videos and Road Implementations

We’ve been implementing AggreBind roads for close to twenty years. Below are a few selected projects to give you an understanding of the range of soils, challenges and environments we have conquered. For more, visit our videos page here

Agriculture haulage roads – Brazil

Pothole repair & high-water table – New Zealand

Sidewalk Stabilization – KSA

Soil Stabilization using RAP – ARAMCO KSA

Sugar plantation – Guatemala

Nepal National Highway

Defence Project – Uruguay

Airstrip – Aero Club Guatemala

Development Project – India

Marketing place – Africa

Build stronger, environmentally friendly, longer-lasting roads with RoadMaster and transform weak soils into rock-solid foundations. With the ability to slash overall project costs by a staggering 40% to 60%, that’s not just efficiency,

it’s revolutionizing the way we build for the future.

RoadMaster FAQs: Your Questions Answered

Can I get a sample of RoadMaster to do a trial section of road?

Absolutely. We can arrange to send lab sample quantities. For doing a trial section of a road, we ship drums and totes. A good size section to test on is 250m – 500m of road. With all orders we provide our clients with full implementation protocol and protocol for lab testing..

Do you offer training if we want to implement it ourselves?

Yes. AggreBind is a product that has been implemented on roads, road bases, airstrips and many other projects by crews both large and small around the world. We follow a strict localization strategy with in-Region Dealers that support the local construction crews and project leaders to educate, provide onsite training and technical support as needed.

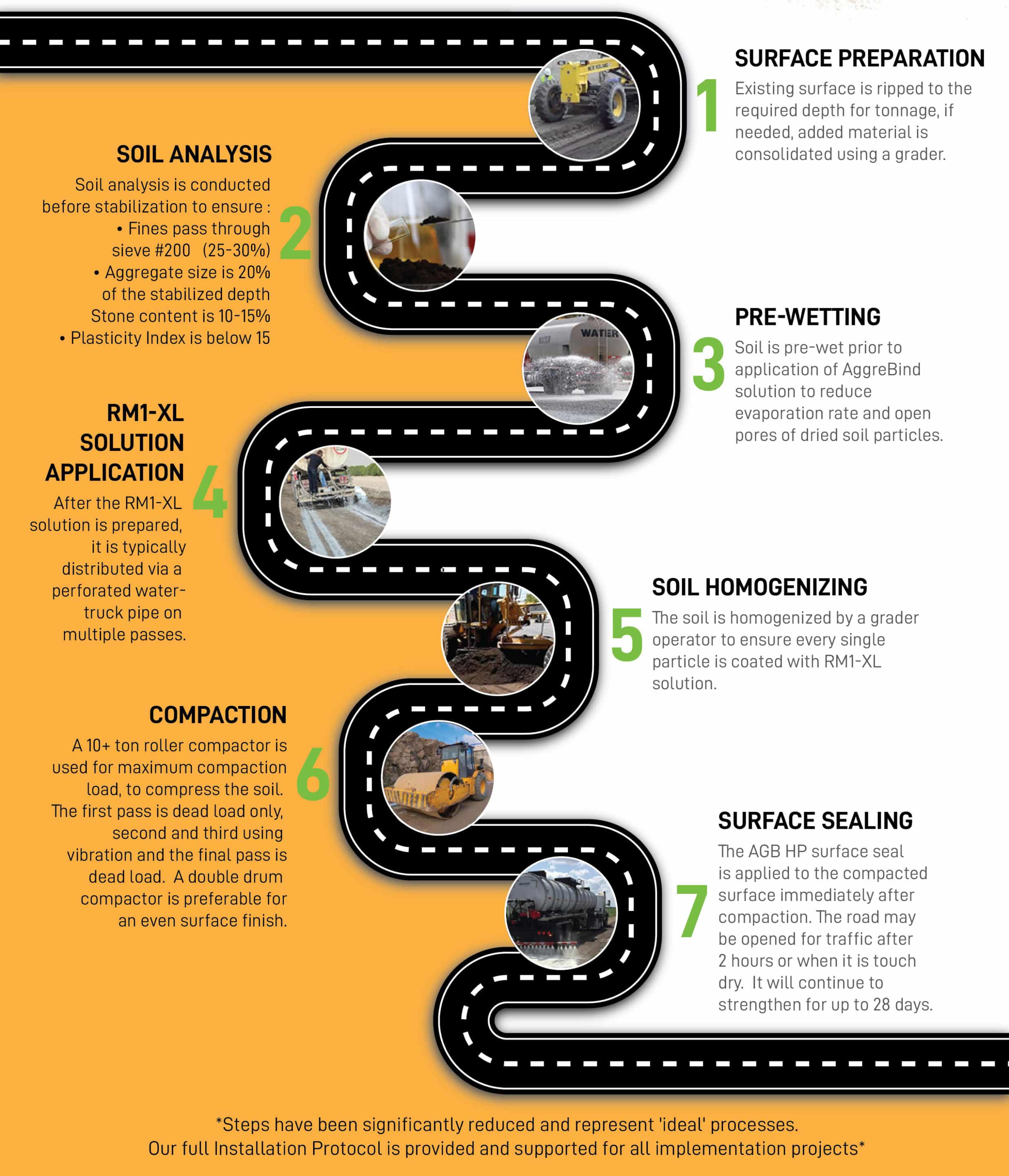

Is RoadMaster application complex, do I need specialised equipment?

Implementing RoadMaster is not complex and depending on the size of the project, only limited equipment may be required. For commercial roads only three pieces of equipment are necessary: a grader, water truck and compactor (preferably double drum). For smaller projects and those in tight spaces, work-arounds are frequently made with what is available locally.

What environmental impact does AggreBind have?

No negative environmental impact. Can be crushed and placed in fields to aerate soil. Composition is non-hazardous, non-toxic and non-leaching.

What happens if an AggreBind road gets damaged? Is it easy to repair?

Yes, repair of AggreBind roads is easy.

Can RoadMaster withstand extreme weather conditions like hot climates, snow or heavy rain?

AggreBind is formulated to be highly durable and withstand various weather conditions, maintaining its strength and stability.

How quickly can a road be built with AggreBind RoadMaster compared to a conventional method?

AggreBind’s simplified application can significantly reduce construction times, leading to quicker completion and faster return on investment

Is RoadMaster strong enough for high-traffic or heavy vehicles?

AggreBind can be customized to meet various strength requirements, making it suitable for roads with varying traffic volumes and loads.

Can waste and recycled materials be used in soil stabilization for road construction using AggreBind?

Yes. AggreBind can effectively bind and stabilize recycled materials like reclaimed asphalt pavement (RAP), reducing reliance on virgin resources. Up to 30% of materials used for the construction of the road can be additional recycled product including pulverised hard plastics, tires, slag and other waste products.

Join Us In Shaping The Future

With AggreBind Solutions

Subscribe To Receive Our Project News