The Vulnerability of Concrete in Saltwater Environments

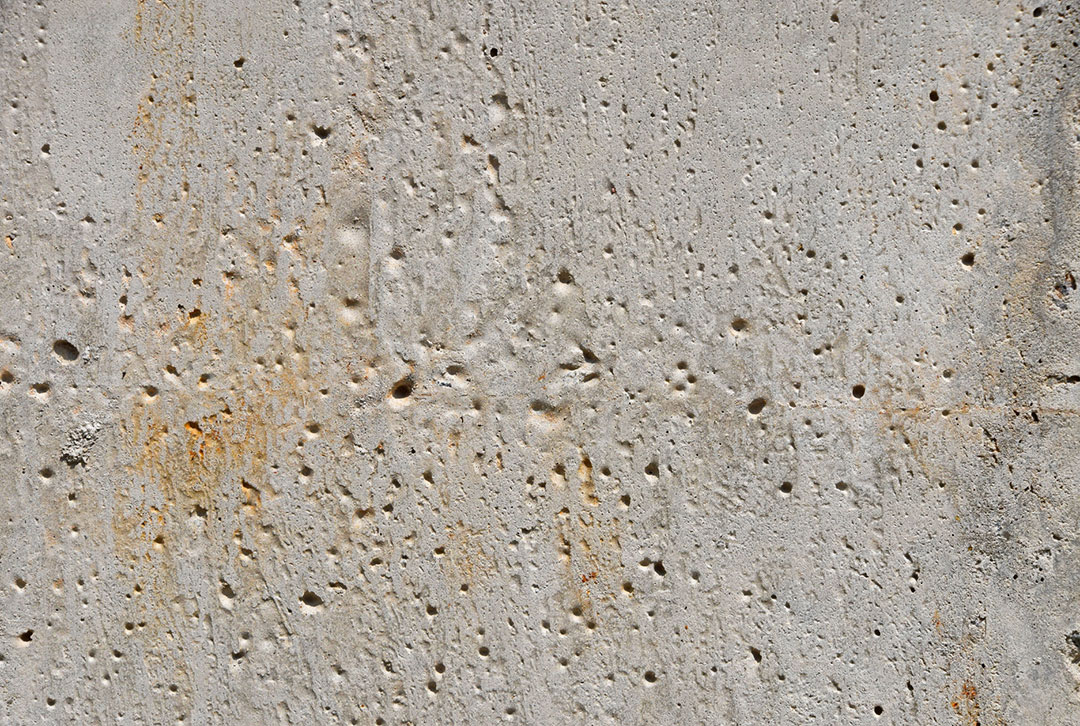

Concrete has been a foundational product in infrastructure development tracing back to ancient civilisations, but its performance can degrade over time when exposed to marine environments. The primary issues arising from the chemical interactions between saltwater, chlorides, and the concrete’s structure and additives. Concrete’s porosity is a key factor in its deterioration, specifically through:

- Chloride-Induced Corrosion: Saltwater’s chloride ions permeate concrete, causing corrosion in its embedded steel reinforcements, with the corroded steel expanding and leading to cracking, spalling, and structural failure.

- Chemical Reactions: Saltwater triggers a chemical reaction like the formation of calcium oxychloride, which are harmful to the concrete’s durability and structural integrity, causing the concrete to expand and crack. Over time, this weakens load bearing structures and increases maintenance and repair cycles.

- Increased Permeability: Over time, exposure to saltwater makes concrete more permeable, accelerating further moisture and chloride ingress and damage that reduces the concrete product lifespan.

These challenges make it essential for the construction industry to explore innovative building materials that are able to withstand harsh coastal environments and weather exposure.

Sustainable Solutions for Saltwater-Resilient Construction

- Hydrophobic Properties: AggreBind works with the cement particles creating a matrixed, water-resistant, hydrophobic structure that prevents chloride infiltration and corrosion of the reinforcing steel, making it an ideal solution for marine construction.

- Proprietary Copolymer Technology: AggreBind’s long-string cross-linking copolymer forms multi-dimensional bonds that strengthen the material and resist cracking, even under extreme environmental stress.

- Non-Porous Structure: AggreBind modified concrete products are less-porous to non-porous, preventing water absorption and salt deposits that degrade conventional concrete, promoting long-term durability and minimising maintenance requirements.

- Eco-Friendly Application: AggreBind supports low-carbon construction by enabling the use of waste concrete, reducing the demand for virgin aggregates and minimizing construction waste, its hydrophobic properties can also allow for a reduction in cement usage which further decreases the environmental impact associated with cement production. Additionally, its non-toxic, non-hazardous and non-leaching properties make it safe for sensitive ecosystems like coastal zones.

AggreCrete: A High-Performance Concrete Additive

- Enhanced Durability in Saltwater: AggreCrete is AggreBind’s PMC product that increases tensile strength and water resistance of concrete, preventing water ingress and surface flaking, making it particularly suitable for precast concrete components and marine infrastructure like seawalls and docks.

- Reduced Carbon Footprint: AggreCrete can reduce cement usage by improving the performance of smaller cement quantities and producing a low carbon concrete, contributing to carbon reduction goals in the construction sector.

- Extended Service Life: By minimizing the effects of chloride penetration and the ingress of water, AggreCrete increases the lifespan of concrete structures in high-salinity environments, minimizing repair cycles and associated costs.

As the construction industry shifts towards low-carbon solutions, AggreBind’s patented solutions combine hydrophobic properties and innovative technologies to achieve cost-effective, durable, and more resilient infrastructure for a sustainable future.